Regular Inspection Procedure

From raw material to packaging, a comprehensive and detailed control process is regulated.

Raw Material Inspection

Each lot of raw material is inspected through full analysis and recorded of all data to ensure its physical properties meet our standard.

Blades Of Screwdrivers Processing

The blade tip dimension is check by DIN standard gauge.

Hardness Test

Blades are proceeded by heat treatment to requested hardness. The tolerence is HRC+/-1

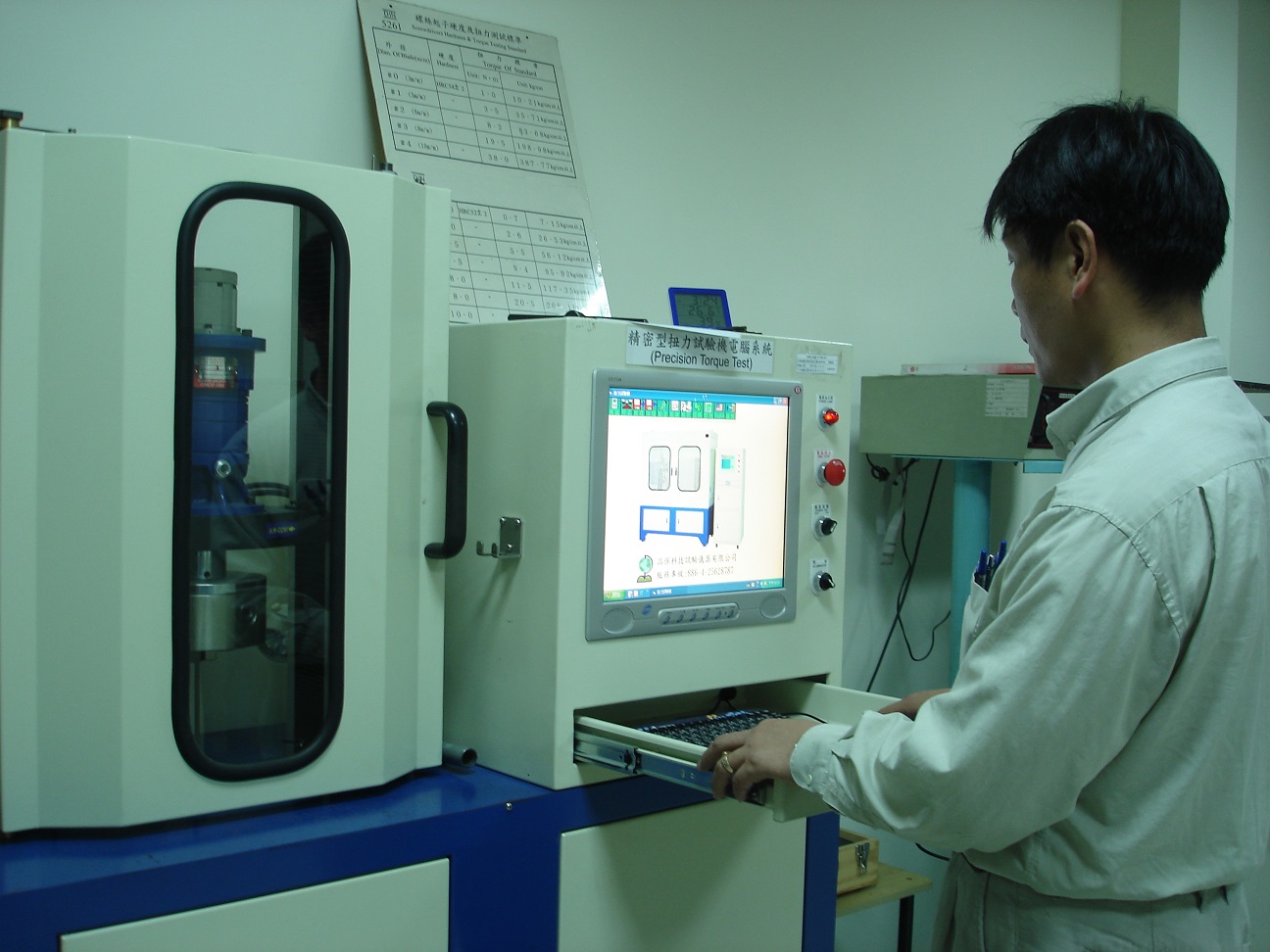

Torque Test

For screwdrivers blade, we ensure the torque performance of chrome-molybdenum steel is 30% higher than DIN standard.

Straighten

To make sure all blades are straight after heat treatment, we straighten and test at the same time.

Electroplate

In order to ensure the rust resistance after plating, salt spray testing is performed to check the appearance.

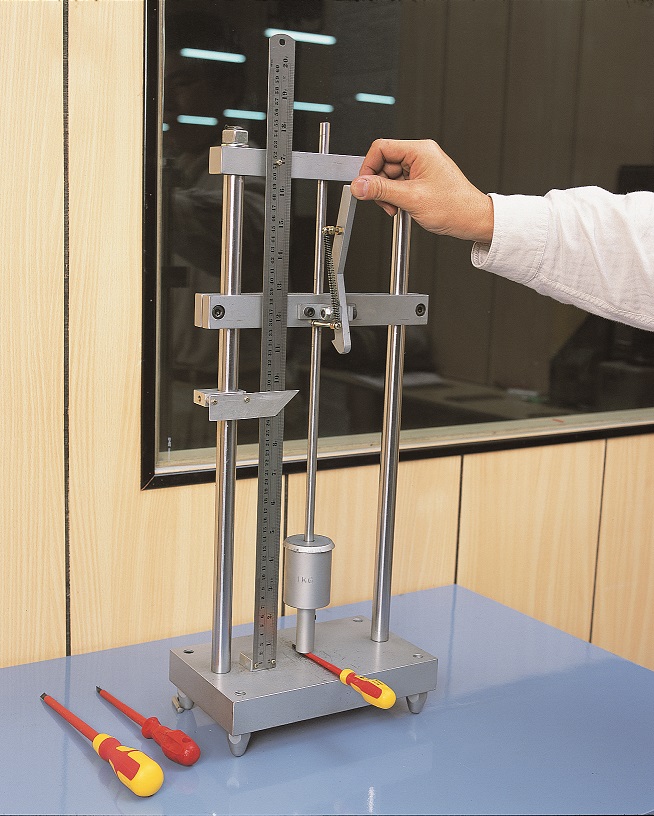

Impact Test

-Normal Temperature: 23℃ ±5℃, H=W/P=2FP

-Low Temperature: -25℃ ±3℃, Stay in the fridge more than 2 hours, (H=W/P=0.6FP) select 3 points of the blade be impacted.

Visual and Final Inspection

After the blade and handle is intergrated into a screwdriver, we do the final inspection as following steps before packing. First, Check the straight line between blade and handle, and ensure the handle is clean. Then, magnetize the blades and pack.